Project Description

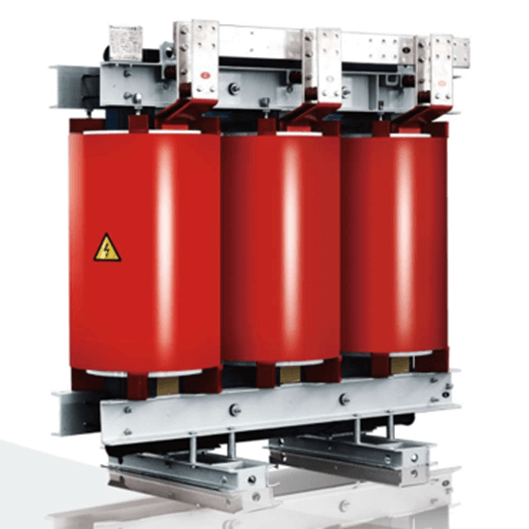

Cast Resin Insulation Dry-type Transformer

The core is made of cold-rolled grain-oriented silicon steel sheet cut in step-lap by automatic cutting line from GEORG, Germany and laminated with method of fifth-order step-by-step stack technology. In this way, no-load performance of the core is greatly improved.

The winding assembly is casted in the vacuum resin casting machine imported from Hedrich, Germany. The resin materials are provided by (HUNTSMAN) CIBA-GEIGY, Switzerland. All these equipment and material ensure good permeability, no bubbles of casted resin, which leads to minimum partial discharge and high capability to withstand short circuit.

The HV and LV winding mate with each other tightly, which ensures solid strength of structure and capability to withstand short circuit and vibration.

Under normal service condition, the service life of dry type transformer is 30 years. No crackle will form on the surface of transformer winding due to temperature variation as long as the transformer runs under normal service condition.

Product Characteristics

Low-noise low-loss

1) The core is made of high quality cold-rolled grain-oriented silicon-steel sheet. The lamination sheets are produced by automatic step-lap core lamination line from GEORG, Germany. Such method improves the distribution of magnetic circuit result in lowering the nose level.

2) Product design adopts CAD software. By selection of high-quality silicon steel sheet and applying lower flux density, noise and no-load loss are reduced due to lower the harmonics in the core.

3) All parts used for clamping apply silicone rubber and flexible elements as buffers in order to reduce the amplitude and noise of components, while the surface of core is coated with a certain thickness of resin, which plays a role of sound-proof.

Non-flammable, no pollution to environment

1) Solid electrical insulation composed of high quality resin and glass fiber could provide with high electrical strength (breakdown voltage ≥34kV/mm) and partial discharge can be controlled in the range of ≤ 5pC.

2) As resin and glass fiber composite materials used in dry-type transformer generate very little heat when in combustion (about 65mJ/kg), the transformer has characteristic of fire-retardant self-extinguishing.

3) Dry-type transformer core is coated with the resin, while the coil is all encapsulated by resin. The transformer can provide relative reliable operation in circumstance of 100% humidity, and has high anti-corrosion ability.

Dry-type transformer also has good advantages such as strong overload capability, good thermal stability, compact size, light weight, easy to install, maintenance-free and so on. .

Dry-type transformer is widely used in high-rise buildings, commercial centers, airports, stations, ports, subway, factories and underground power distribution stations.

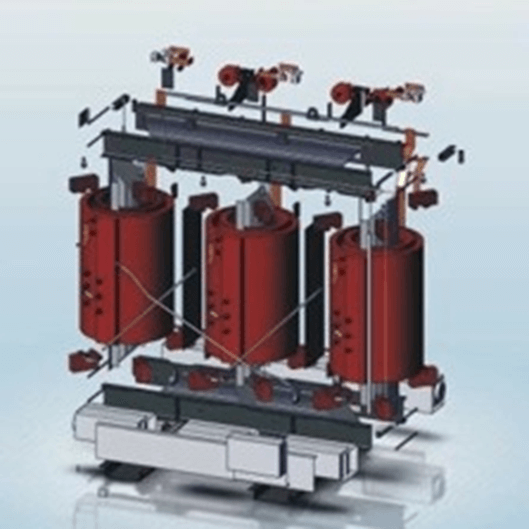

Core

The core is made of high quality cold-rolled grain-oriented silicon-steel sheet, laminated by automatic step-lap core lamination line imported from GEORG, Germany. Such method improves the distribution of magnetic circuit result in lowering the nose level.

By selection of high-quality silicon steel sheet and applying advanced technology, equipment, no-load performance of transformer is improved. Compared with conventional core, no-load loss, no-load current and noise level are reduced respectively by 5%~6%, 20%~30%, 6%.

Cast-resin high-voltage coil

High-voltage coil applies fractionation-layer structure, casted with Swiss Huntsman (the former Swiss ClBA) resin materials, Germany) and by HEDRICH vacuum casting equipment. Low-voltage coil applies foil structure. Advanced technology ensures little partial discharge of coil and strong ability to withstand short circuit.

Tapping range of high-voltage coil

Un ± 5% and Un ± 2 × 2.5% OCFC, as well as Un ± 4 × 2.5% OLTC.

Temperature control device

With fault alarm, over-temperature alarm, over-temperature tripping, three-phase polling, start and stop air-force cooling device and other functions. It can also configure computer remote control interface.

Cooling device

Radial flow fan has advantages of low noise, good cooling effect, easy installation. It also improves the operation capacity by installing fans.

Specification of 10kV (SC(B)9 Series) Dry Type Distribution Transformer

|

Model |

UK% | PO (w) | PK (75℃) (w) |

IO (%) |

LP dB (A) |

GT (kg) |

Dimension (mm) | |||||||||

| a | b | c | d | e | f | g | h | k1 |

k2 |

|||||||

|

sc9-30/10 |

4 | 210 | 650 | 1.6 | 44 | 320 | 870 | 600 | 860 | 500 | 400 | 765 | 198 | 225 | 150 | 75 |

|

sc9-50/10 |

295 | 920 | 1.6 | 44 | 350 | 800 | 600 | 935 | 500 | 400 | 875 | 205 | 235 | 150 | 75 | |

|

sc9-80/10 |

400 | 1270 | 1.4 | 45 | 520 | 960 | 600 | 1040 | 500 | 400 | 970 | 214 | 243 | 150 |

75 |

|

| sc9-100/10 | 425 | 1460 | 1.4 | 45 | 550 | 960 | 600 | 1040 | 500 | 400 | 970 | 214 | 243 | 150 |

75 |

|

|

sc9-125/10 |

500 | 1710 | 1.2 | 46 | 720 | 1000 | 600 | 1080 | 500 | 400 | 1070 | 215 | 249 | 150 | 75 | |

| sc9-160/10 | 580 | 1960 | 1.2 | 46 | 770 | 1030 | 650 | 1130 | 500 | 400 | 990 | 225 | 270 | 150 |

75 |

|

| sc9-200/10 | 660 | 2340 | 1.0 | 47 | 850 | 1060 | 720 | 1130 | 500 | 550 | 1048 | 223 | 257 | 150 |

75 |

|

|

SCB9-250/10 |

770 | 2540 | 0.8 | 47 | 1010 | 1120 | 720 | 1175 | 500 | 550 | 1017 | 240 | 268 | 390 | 75 | |

|

sB9-315/10 |

910 | 3200 | 0.8 | 48 | 1145 | 1180 | 710 | 1130 | 500 | 550 | 988 | 281 | 275 | 395 |

150 |

|

| sB9-400/10 | 1000 | 3680 | 0.8 | 48 | 1360 | 1220 | 720 | 1185 | 500 | 550 | 1085 | 292 | 283 | 410 |

150 |

|

|

sB9-500/10 |

1200 | 4510 | 0.6 | 48 | 1600 | 1250 | 830 | 1270 | 660 | 660 | 1175 | 297 | 288 | 425 |

150 |

|

|

sB9-630/10 |

1390 | 5430 | 0.6 | 49 | 1900 | 1300 | 830 | 1370 | 660 | 660 | 1275 | 310 | 298 | 440 | 150 | |

|

sB9-630/10 |

6 | 1350 | 5510 | 0.6 | 49 | 1830 | 1340 | 830 | 1295 | 660 | 660 | 1200 | 295 | 284 | 450 |

150 |

| sB9-800/10 | 1630 | 6430 | 0.5 | 50 | 2245 | 1420 | 880 | 1395 | 660 | 660 | 1270 | 320 | 298 | 480 |

150 |

|

|

sB9-1000/10 |

1830 | 7510 | 0.5 | 50 | 2565 | 1500 | 880 | 1390 | 820 | 660 | 1265 | 330 | 308 | 505 | 150 | |

|

sB9-1250/10 |

2170 | 8960 | 0.5 | 52 | 3160 | 1610 | 900 | 1500 | 820 | 660 | 1355 | 342 | 321 | 545 |

200 |

|

| sB9-1600/10 | 2530 | 10850 | 0.5 | 52 | 3875 | 1730 | 920 | 1575 | 820 | 660 | 1430 | 375 | 332 | 585 |

200 |

|

|

sB9-2000/10 |

3360 | 13360 | 0.4 | 53 | 4480 | 1770 | 960 | 1695 | 820 | 660 | 1520 | 381 | 339 | 595 | 200 | |

| sB9-2500/10 | 4000 | 15870 | 0.4 | 54 | 5385 | 1840 | 990 | 1855 | 1070 | 820 | 1670 | 401 | 345 | 620 |

250 |

|

Technical parameters & Outer dimensions for SC(B)9 Series 35kV dry-type distribution transformer

|

Model |

H.V. (kV) | L.V. (kV) | Tapping Range % |

UK % |

PO (w) |

PK (75℃) (w) |

IO (%) |

LP dB (A) |

GT (kg) |

Vector Group |

LxWxH (Transformer) (mm) |

Rail Distance (mm) |

| SC9-800/35 | 33-38.5 | 3.15

(or) 6 6.3 10 10.5 11 |

±5

(or) ±2×2.5 |

6 | 2500 | 8600 | 0.6 | 50 | 3250 | Yyn0 |

1880×1000×1925 |

820×660 |

|

SC9-1000/35 |

2950 | 10000 | 0.6 | 50 | 3900 | (or) | 1970×1000×2100 | |||||

| SC9-1250/35 | 3480 | 11800 | 0.6 | 52 | 4800 | Yd11 |

2050×1000×2180 |

|||||

|

SC9-1600/35 |

4100 | 14200 | 0.5 | 52 | 5500 | (or) | 2150×1000×2250 | |||||

| SC9-2000/35 | 7 | 4700 | 16700 | 0.5 | 53 | 6230 | Dyn11 | 2200×1200×2300 |

1070×820 |

|||

|

SC9-2500/35 |

5400 | 20000 | 0.5 | 54 | 7200 | 2300×1200×2350 | ||||||

| SC9-3150/35 | 8 | 6700 | 22500 | 0.4 | 57 | 9850 |

2500×1200×2430 |

|||||

|

SC9-4000/35 |

7750 | 27000 | 0.4 | 57 | 10500 | 2600×1600×2535 | 1475×1475 | |||||

|

SC9-5000/35 |

9200 | 32800 | 0.4 | 58 | 12800 |

2880×1675×2580 |

||||||

| SC9-6300/35 | 10500 | 37500 | 0.3 | 58 | 15960 |

2950×1675×2650 |

||||||

|

SC9-8000/35 |

9 | 12000 | 42300 | 0.3 | 60 | 18210 | Yyn0 | 3000×1850×2850 | ||||

|

SC9-10000/35 |

±3×2.5% | 13500 | 51080 | 0.3 | 60 | 23800 | (or) |

3100×1850×3070 |

2×1020×1475 |

|||

| SC9-12500/35 | 16500 | 57380 | 0.2 | 60 | 29600 | Ynd11 |

3300×1850×3335 |

|||||

|

SC9-16000/35 |

19800 | 66360 | 0.2 | 62 | 36500 | (or) | 3800×1900×3380 | |||||

| SC9-20000/35 | 10 | 23000 | 74660 | 0.2 | 62 | 40200 | Dyn11 |

3850×1900×3415 |

Video will be updated soon.