Project Description

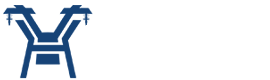

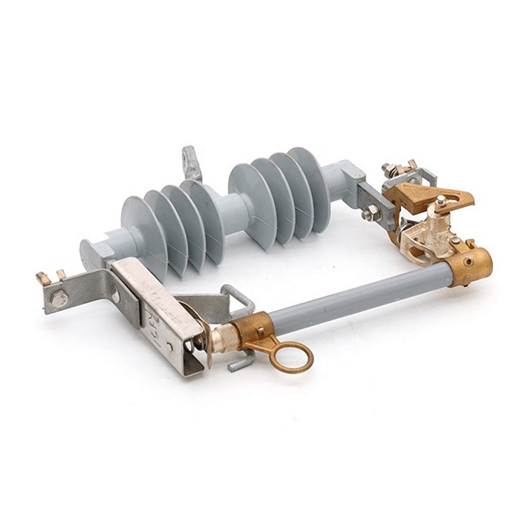

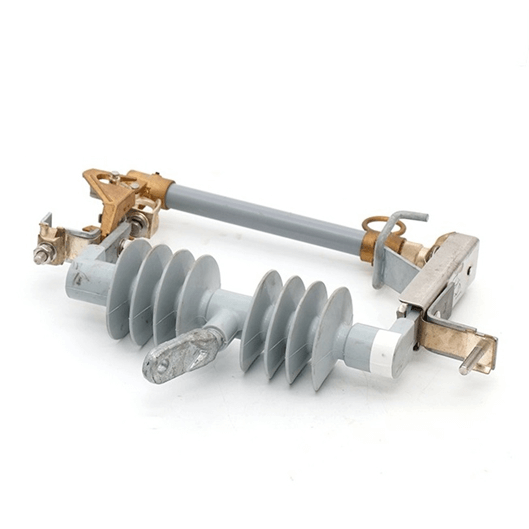

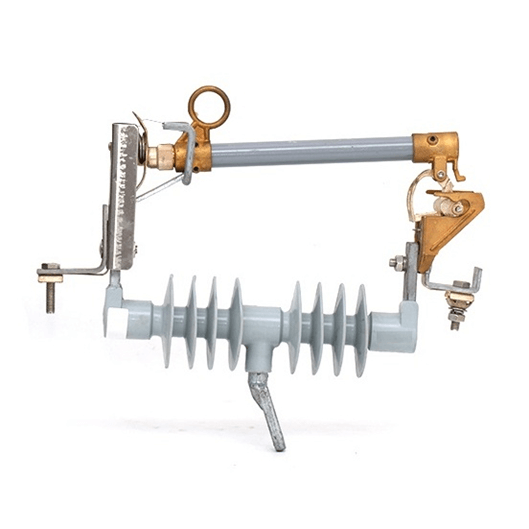

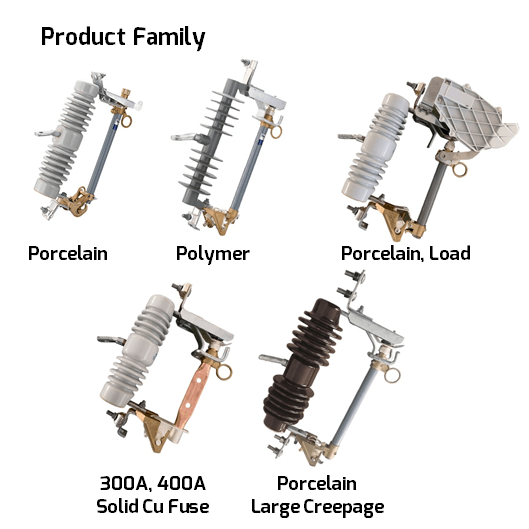

12-15kV Polymer Drop Out Fuse Cutout

Application of Expulsion Fuse Cutout:

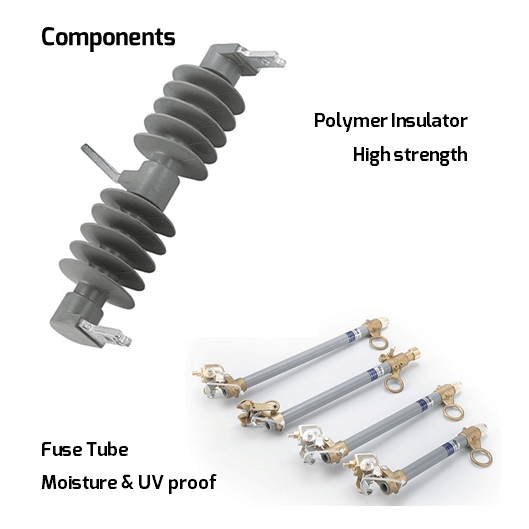

Generally, fuse cut-out contains following parts: (1) Insulator; (2) Metal parts; (3) Fuse tube; (4) Fuse element (link).

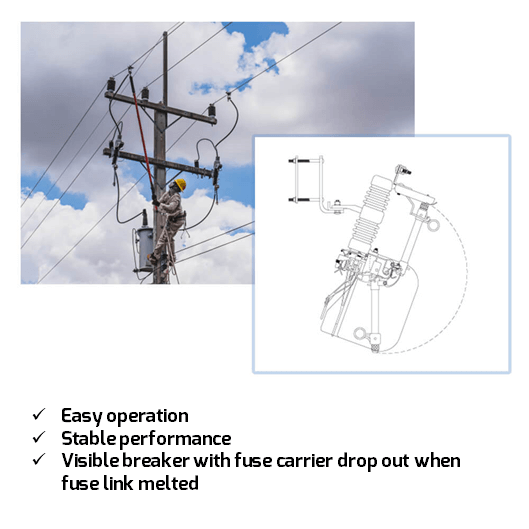

Connected with incoming feeder of distribution transformer or distribution lines, high-voltage drop-out fuse cut-out mainly protect transformer or lines form short circuit and overhead, and on/off loading current. Cut out fuse is composed of insulators and fuse tube/carrier. Static contacts are fixed on two sides of insulator support while moving contacts are installed on two ends of fuse tube/carrier. Fuse tube/carrier is composed of inner arc-extinguishing tube, outer phenolic compound paper tube or epoxy glass tube.

Drop out fuses and load-drop fuses are outdoor high voltage protection appliances. They are installed on the high voltage side of the distribution transformer or on the branch line of the distribution line, used as a short circuit of the transformer and the line, overload protection and cut out load current.

Dropout fuse is composed of two parts: An insulating bracket and a fuse tube. The static contact is installed at two ends of the insulating bracket, the movable contact is installed at both ends of the fuse tube, and the fuse tube is composed of an inner arc extinguishing tube and an outer layer.

It consists of a phenolic paper tube or an epoxy glass tube. The load drop fuse enhances the elastic auxiliary contact and the arc extinguishing cover to divide and combine the load current.

Composite (silicone rubber) type has been implemented in the utility market for more than 30 years and is becoming the main choice for application at distribution, transmission and substation. With exceptional performance durability and insulation characteristics, silicone rubber fuse cut-out has ability to maintain its natural hydrophobicity over its service life and maintain stability against high temperatures, flashovers and UV radiation. Composite fuse cut-out weighs less compared with porcelain counterparts. The insulator body is produced by integrative silicone injection mold that encapsulates the upper and lower mounting provision as well the center-mounting pin. This design eliminates the potential for moisture ingress and increases the rigidity as well as decreases the flexion on the silicone body under interruption and re-fusing.

Circuit switching off processes by fuse cut-out is as follow:

In case of any deficiency or problem in main lines, a short connection takes place. This short connection flows in the main lines. As soon as the current passes, the voltage of the main line drops rapidly and reaches to zero. The energy created by current passage of short connection melts the fuse element. At melting status, the temperature of fuse element (link) increases the resistance of fuse (element); and current passage decreases the pressure of both tips of fuse. When the element is melted, the spark arc current passes through the fuse; the current resistance increases quickly. So the pressure increases at both tips of fuse. The extra pressure, which not provided by main line, would be provided by circuit inductivity of trans (e=1 di/dt); and finally this inductivity causes the current to drop zero. It should be mentioned that these processes take place in a few milli-seconds and disconnection of fuses will occur in a few milli-seconds. For example, when 9 amp current passes through a 25 Amp fuse, this current will be cut in 2.7 seconds.

| Rated Voltage (KV) |

Rated Current (A) |

Breaking current (A) |

BIL (KV) |

Power frequency withstand voltage (kV) |

Creepage distance (mm) |

Weight (kgs) |

Dimension (cm) |

| 12-15 | 100 | 8000 | 110 | 40 | 250 | 5.5 | 46*36*9.5 |

| 12-15 | 200 | 10000 | 110 | 40 | 250 | 6 | 46*36*9.5 |

Video loading, please wait…

Video loading, please wait…

Video loading, please wait…